The European Chamber of Commerce in Vietnam (EuroCham) successfully hosted a specialized industrial seminar titled “Unlocking the New Era of Smart Factories,” aimed at advancing Vietnam’s transition to Industry 4.0.

The event brought together manufacturing executives, technology leaders, and industry experts to discuss integrating cutting-edge technologies into operational workflows, enhancing Vietnam’s competitive edge on the global manufacturing map.

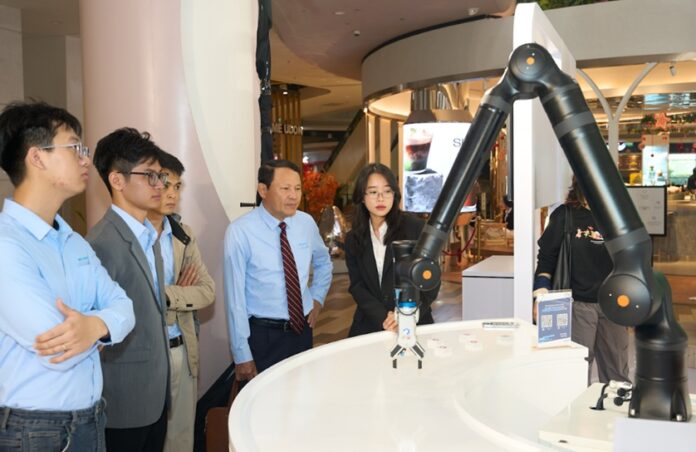

Held at AEON Mall Ha Dong, Hanoi, with contributions from experts at Bosch Vietnam—a global technology leader—the seminar addressed a pressing challenge: As neighboring countries accelerate industrial digitalization, Vietnamese manufacturers face growing pressure to boost productivity, enhance global competitiveness, and build resilient, future-ready operations.

Vietnam at the Crossroads of Industrial Transformation

Vietnam’s industrial sector is undergoing rapid modernization, driven by global supply chain shifts, heightened productivity demands, and a strong commitment to digitalization. Companies successfully adopting smart factory principles have reported significant improvements: 20-30% productivity gains, reduced downtime, and enhanced product quality.

This shift is more than a technological upgrade; it’s a strategic move to solidify Vietnam’s position as a regional manufacturing hub, attracting high-value investments. In an era of globalized supply chains and sustainability demands, smart factories are essential for manufacturers to remain competitive and grow.

Conversely, factories slow to adopt these changes risk falling behind, while early adopters position themselves as regional and global leaders.

Bosch Experts Highlight Key Pillars of Smart Factory Development

At the seminar, Bosch Rexroth—Bosch’s Drive and Control division and a global provider of hydraulic and factory automation solutions—outlined the core pillars of operational excellence in smart factories.

Foundational technologies such as servo motors, welding systems, linear motion technology, and 7-axis robots from Bosch Rexroth have long been trusted by global manufacturers. However, the seminar spotlighted upgraded versions and next-generation technologies, integrating IoT and AI directly into equipment. This enables more connected, transparent, and flexible automation than ever before.

At the intersection of AI and IoT, Bosch Rexroth introduced the ctrlX CORE and ctrlX Automation ecosystem—a fully open, modular, and flexible Industry 4.0 control platform. Dubbed the “smartphone of automation,” ctrlX is one of the most advanced control platforms today, redefining IoT and AI limits for future factories. It enables centralized device management, efficient coordination, and AI-driven operational optimization.

“Bosch Rexroth understands Vietnam’s manufacturing realities,” said Vu Duc Son, Business Director of Factory Automation at Bosch Rexroth Vietnam. “It’s not just about adopting new technology but integrating it seamlessly with existing systems to create a cohesive ecosystem.”

“With open platforms like ctrlX CORE, we offer businesses the flexibility to transform at their own pace, connecting legacy equipment with new intelligence without immediate massive investment,” Son emphasized.

Additionally, Hu Qian, Director of Supply Chain Services at Bosch Vietnam’s APAC Center, presented case studies demonstrating how leading manufacturers leverage data analytics and automation to achieve measurable operational improvements: increased output, higher productivity, and optimized efficiency. For Vietnam, these benefits translate into competitive advantages against lower-cost countries while maintaining international quality standards.

Smart Factories: Vietnam’s Path to High-Tech Manufacturing Leadership

The seminar outlined a practical roadmap for Vietnam’s transformation. Manufacturers can adopt a phased approach—starting with predictive maintenance and real-time production monitoring, then expanding to fully integrated smart factory ecosystems. This minimizes implementation risks while ensuring investment efficiency.

Crucially, the event highlighted broader opportunities for Vietnam on the global manufacturing stage. Regional leaders in Industry 4.0 adoption will attract foreign direct investment (FDI), create high-skilled jobs, and drive technology transfer. This is Vietnam’s chance to establish itself as Southeast Asia’s high-tech manufacturing hub—moving beyond cost-based competition as regional rivals accelerate digitalization.

“This transformation isn’t about technology replacing human expertise; it’s about amplifying Vietnam’s manufacturing capabilities,” stated Andre de Jong, Vice President and Managing Director of Bosch Vietnam. “Bosch Vietnam aims to help Vietnamese manufacturers unlock Industry 4.0’s full potential, securing Vietnam’s position in the global supply chain for decades.”

As a global technology leader, Bosch is committed to being a strategic partner in Vietnam’s smart factory journey—providing advanced equipment, software, localized consulting, capacity building, and long-term support tailored to Vietnam’s unique manufacturing challenges.

TH (Tuoitrethudo)