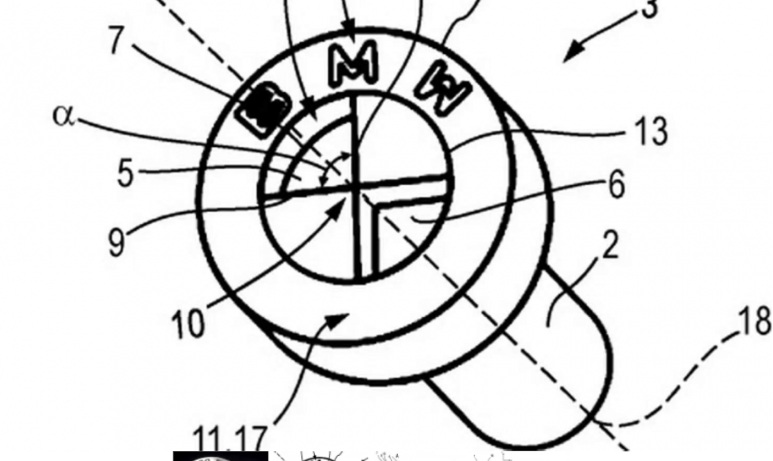

BMW recently made headlines by filing a patent for a unique screw featuring the brand’s iconic logo as its head.

Instead of conventional hex or Phillips designs, this screw is divided into four sections with alternating recessed and flat surfaces, requiring specialized tools for installation and removal. This move has sparked concerns that the automaker is intentionally restricting DIY repairs and limiting access for independent service shops.

According to the patent filing, BMW plans to use these “proprietary” screws in critical structural and semi-structural locations, such as seat mounts and interior-to-body connections—areas frequently accessed during maintenance or upgrades. By introducing a proprietary fastener, BMW effectively forces vehicle owners and third-party technicians to rely on authorized dealerships for even minor technical tasks, as standard tools become incompatible.

The patent news quickly ignited debates across social media and automotive forums. Many expressed concerns that this design, if implemented, would increase dependency on official service networks, driving up repair costs. Others approached the issue with humor, predicting that aftermarket tools would soon surface on e-commerce platforms if BMW proceeds with the screw’s production.

Industry experts caution, however, that patent filings do not guarantee real-world application. Numerous BMW patents have remained conceptual for decades without ever appearing on production vehicles. While this design could enhance aesthetics or security, its implementation would pose significant cost challenges for customers prioritizing at-home maintenance flexibility.

TH (Tuoitrethudo)