If 32 minutes is all it takes to cook a simple meal or watch two sitcom episodes, then at the Rolls-Royce factory in Goodwood, this is the precise time allotted for each stage of assembling the world’s most luxurious cars.

Each car, averaging around £440,000 in value, must be completed on schedule at 14 stations per shift to avoid delaying deliveries for VIP customers who have waited up to two years.

A time machine with second-by-second precision

In reality, the actual working time for each station is 28 minutes, with 4 minutes set aside for contingencies such as technical issues or missing parts. Each day, the two-shift assembly line at Goodwood produces 28 cars, a small number compared to mass-market manufacturers, but fitting for the level of personalization and craftsmanship that Rolls-Royce pursues.

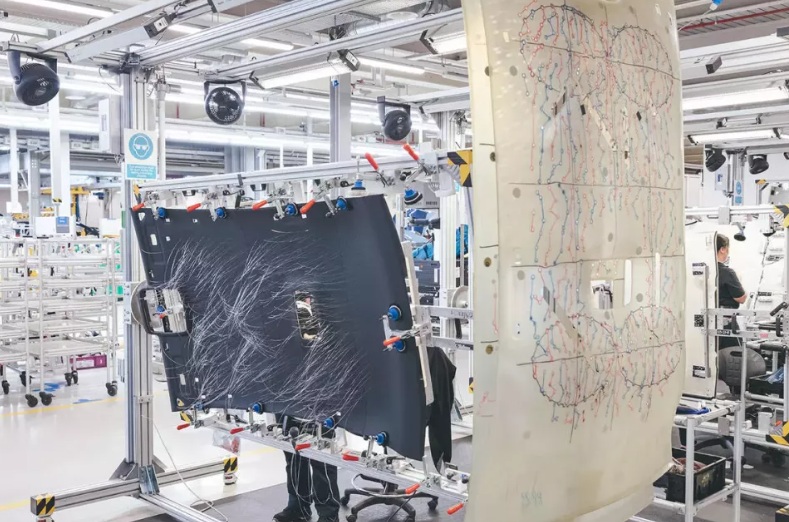

Here, there are no industrial robots. Instead, 600 skilled hands work in harmony like ballet dancers, assembling headliners, dashboards, door panels, and every stitch of the interior. Everything adheres to the rigorous “on-time” production process, where components and parts arrive precisely on the minute from the internal warehouse.

Rolls-Royce Electrification: Challenges and Precision

With the introduction of the brand’s first electric car, the Rolls-Royce Spectre, the engineers at Goodwood face the challenge of maintaining traditional precision while adapting to fundamental technological changes. The Spectre is equipped with a dual-motor, all-wheel-drive system and a 102 kWh lithium-ion battery and is hand-built just like the Ghost, Cullinan, and Phantom models.

Notably, the Goodwood factory did not build a separate assembly line for electric vehicles. Instead, the Spectre is integrated into the same production line as the internal combustion engine models, a decision that demands high flexibility but provides instant adaptability to market fluctuations.

“If demand for a particular model increases or decreases, we can adjust immediately without being constrained by a rigid production structure,” said Greg Denton, Director of Manufacturing at Rolls-Royce.

New Structure, Old Philosophy

All Rolls-Royce models today, including the Spectre, utilize the Architecture of Luxury platform, a flexible and unified chassis that supports diverse production without major adjustments. However, integrating an electric powertrain into a system designed for internal combustion engines presented challenges.

For instance, the powertrain installation area had to be completely rebuilt to accommodate the Spectre’s heavy battery pack. Three new lifts were added to support the car during the final installation phase, instead of returning it to the conveyor as before. The car also needed to be fitted with wheels earlier so it could move autonomously once completed.

During a two-week summer break, 150 contractors transformed this critical production area, one of the largest overhauls since the Goodwood factory began operations in 2003.

Electrification Without Compromising Tradition

The Rolls-Royce Spectre is not just the brand’s first electric car, but also a testament that a 120-year-old company can embrace a new era without sacrificing its identity. Many production processes at the factory remain unchanged, and some have even become simpler without the internal combustion engine.

Workers who once installed exhaust systems now route high-voltage cables. The fuel-filling station has become a charging station. The engine installation station is now where batteries are installed. “In fact, a lot of things remain the same, and that’s what surprised us the most, a pleasant surprise,” said Denton.

In a world rapidly transformed by technology and electrification pressures, Rolls-Royce stays true to its core philosophy: never compromising on perfection. And in just 32 minutes – the time it takes to boil a pot of water, the luxury carmaker adds another chapter to its grand history: the Spectre rolls out, quietly yet majestically.

TH (Tuoitrethudo)

“TMT Motors Postpones Baojun E100 Launch, Introduces Cheaper Nano S05 Electric Car”

“TMT Motors boasts an impressive feat of engineering with their Nano S05, as it is predicted that the daily electricity costs to run this vehicle will be a mere one-third of that of a conventional gasoline-powered motorcycle. This innovative electric vehicle offers a cost-effective and environmentally friendly alternative to traditional transport, providing a glimpse into a sustainable future.”

The First Importer of Rolls-Royce Cars to Vietnam Reveals Heavy Losses Over Seven Years: Only Sold Over 20 Cars

“After a successful 7-year stint as the CEO of Rolls-Royce Vietnam, the former executive reveals a unique insight into his tenure. With a focus on a different, undisclosed profitable aspect of the business, he managed to sell over 20 of these luxurious vehicles before stepping down. A remarkable achievement indeed.”